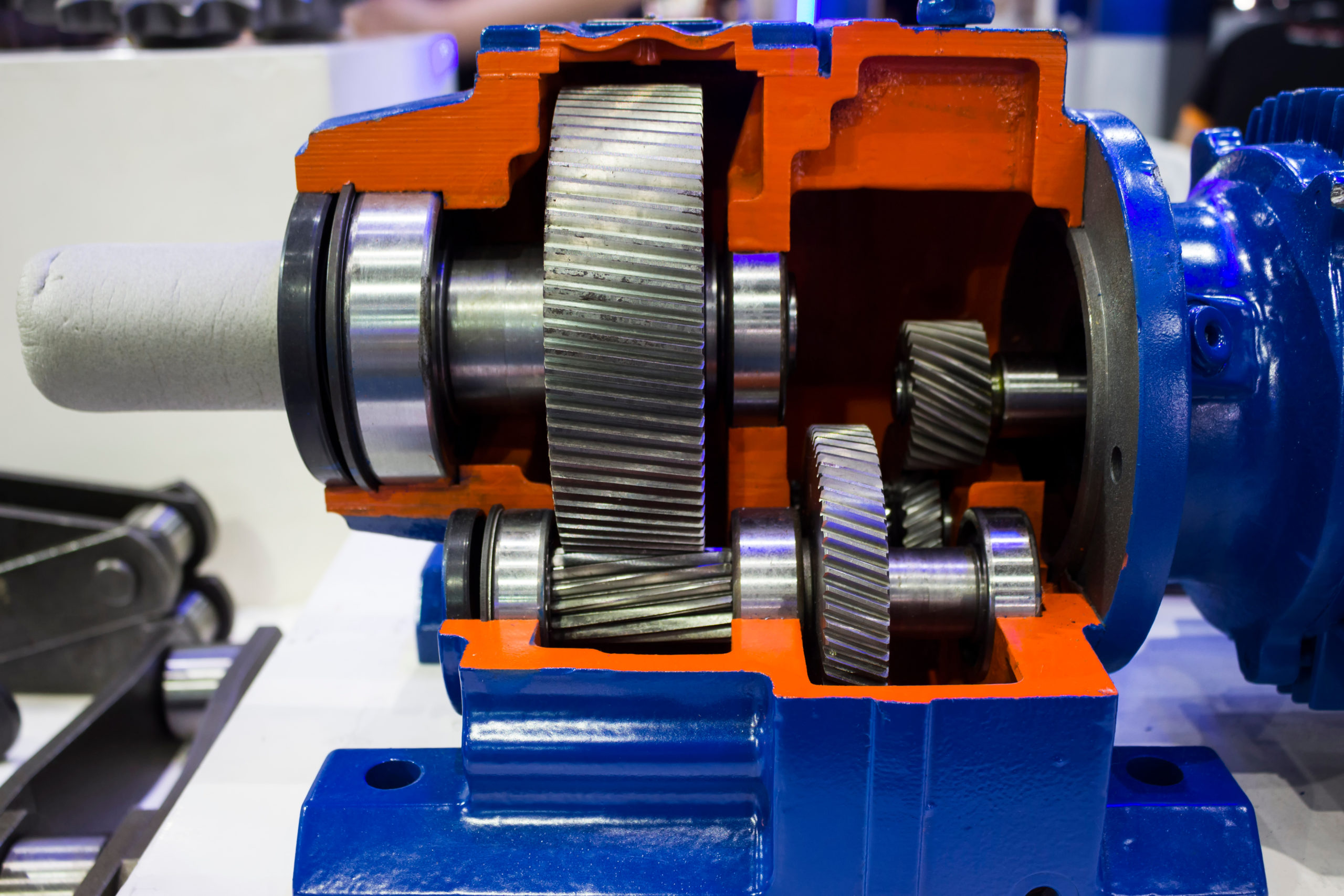

Gear pumps are routinely used in high-pressure applications. They are engineered with reinforced components and specialized seals to withstand the extreme forces of boosting fluid pressure. The drive mechanism gives rotary motion to the rotor gear, which causes the idler gear to rotate. The tight clearances between the gear teeth and the stationary crescent seal minimize fluid from internally leaking backward.

High Efficiency

Liquiflo gear pumps have a high-efficiency level and transfer fluids with minimum energy loss. They can operate at higher speeds and deliver high-pressure capabilities, making them ideal for hydraulic systems. When a gear pump is running, the two rotating gears unmesh at the suction side of the pump. This creates a vacuum and draws fluid from the surrounding area into the pump. Once the fluid enters the gear teeth, it is imprisoned and can only migrate to the discharge side of the pump, where it is pushed out under force. The running clearances between the gear faces, gear tooth crests, and housing cause a slight loss to the pumped volume, known as flow slip. This is nearly constant at different speeds and flows and changes linearly with pressure. Therefore, gear pumps must be run close to their maximum rated speed to achieve high volumetric efficiency. They also require lubrication to ensure the gears do not rub together, causing damage.

Low Maintenance

Gear pumps require less maintenance than other pump types. They only have a few moving parts, which reduces the likelihood of mechanical failure. The operation of a gear pump depends on tight clearances between the gear teeth and the chamber. If the seals or bearings are worn, it can cause leakage. Inspecting the shaft seals and replacing them when necessary is essential to prevent fluid loss. The teeth of the gears mesh together, creating a series of cavities between them (inlet stages). These cavities trap liquid inside and transport it towards the outlet port. Gear pumps aren’t recommended for use with fluids containing suspended solids because the abrasive particles can damage the pump’s internals. They are also unsuitable for applications that need long periods of dry operation. They can suffer from increased wear and noise, so it’s best to use alternative pumps for these applications.

Reliability

Gear pumps have fewer moving parts than other positive-displacement pump types, leading to a lower failure rate. Nevertheless, other factors contribute to reliability. For example, a gear pump cannot handle fluids containing suspended solid particles. This can cause clogging and damage to the internal components. Additionally, a gear pump must be adequately lubricated with the manufacturer-recommended product to prevent excessive friction that can cause overheating and reduced efficiency. Gear pumps also rely on tight clearances between their moving parts. Therefore, inspecting these areas regularly for signs of wear and tear is essential. This is especially true for shaft bearings, which can be inspected by inserting a piece of paper between the gear teeth and casing. This test will help you determine whether the bearings are worn down and must …

Brighter Thinking drives our strategy to science: a solid foundation of analysis from main instructional thinkers, skilled authors and science academics all over the world underpins the resources we publish to assist college students learning science. CSIRO – gives science applications and sources for faculties, special occasions round Australia and a spread of at-residence science for all ages. The Automotive Experience associate diploma program is a sequence of courses designed to organize college students for careers inside the automotive service and restore profession.

Brighter Thinking drives our strategy to science: a solid foundation of analysis from main instructional thinkers, skilled authors and science academics all over the world underpins the resources we publish to assist college students learning science. CSIRO – gives science applications and sources for faculties, special occasions round Australia and a spread of at-residence science for all ages. The Automotive Experience associate diploma program is a sequence of courses designed to organize college students for careers inside the automotive service and restore profession. From topics like Behavioral Psychology to conventional studying, these web sites present barrage of free learning selections to varsity college students at numerous ranges. The consultants say: One of the best on-line courting websites for those on the lookout for long-term relationships with skilled people, customers full a persona test to measure compatibility with potential dates utilizing psychometric evaluation.

From topics like Behavioral Psychology to conventional studying, these web sites present barrage of free learning selections to varsity college students at numerous ranges. The consultants say: One of the best on-line courting websites for those on the lookout for long-term relationships with skilled people, customers full a persona test to measure compatibility with potential dates utilizing psychometric evaluation. Courting is a stage of romantic relationships in people whereby two folks meet socially with the intention of every assessing the other’s suitability as a potential companion in an intimate relationship It is a form of courtship , consisting of social actions performed by the couple, both alone or with others. Retaining many of these unrealistic expectations can make any potential accomplice appear inadequate and any new relationship feel disappointing. Courting can be life-altering especially due to how folks can learn their lessons the exhausting means.

Courting is a stage of romantic relationships in people whereby two folks meet socially with the intention of every assessing the other’s suitability as a potential companion in an intimate relationship It is a form of courtship , consisting of social actions performed by the couple, both alone or with others. Retaining many of these unrealistic expectations can make any potential accomplice appear inadequate and any new relationship feel disappointing. Courting can be life-altering especially due to how folks can learn their lessons the exhausting means. In order to help a complete understanding of the technology, the curriculum consists of laboratory programs which provide palms-on experiences in figuring out and sustaining the component components of computing equipment and the processes and procedures for connecting networks utilizing routers and associated tools. Laptop hardware engineers are tasked with designing, growing and supervising the manufacturing and installment of computer hardware, which includes keyboards, modems, printers, laptop programs, chips and circuit boards. Eligible college students can participate in an eight-week work practicum placement in the computer business to provide them relevant sensible expertise, learn on-the-job procedures, and develop invaluable contacts.

In order to help a complete understanding of the technology, the curriculum consists of laboratory programs which provide palms-on experiences in figuring out and sustaining the component components of computing equipment and the processes and procedures for connecting networks utilizing routers and associated tools. Laptop hardware engineers are tasked with designing, growing and supervising the manufacturing and installment of computer hardware, which includes keyboards, modems, printers, laptop programs, chips and circuit boards. Eligible college students can participate in an eight-week work practicum placement in the computer business to provide them relevant sensible expertise, learn on-the-job procedures, and develop invaluable contacts. The Canadian Middle of Science and Schooling was established in 2006. 35 , 36 For example, a randomized controlled educational trial of surgical novices revealed improved transfer of surgical abilities from the simulated setting (skills coach) to the working room (animal model) when the intervention group was uncovered to the deliberate apply model and skilled past proficiency.

The Canadian Middle of Science and Schooling was established in 2006. 35 , 36 For example, a randomized controlled educational trial of surgical novices revealed improved transfer of surgical abilities from the simulated setting (skills coach) to the working room (animal model) when the intervention group was uncovered to the deliberate apply model and skilled past proficiency. We now have been aiding firms with printing, enterprise varieties, promoting and marketing options, stationery, envelopes and imprinted promotional products since 1986. Improvement of international enterprise may contribute to an anticipated enhance in demand for administration analysts. A degree in enterprise and finance gives you the chance to access a range of graduate positions around the globe – in monetary administration, investment banking, promoting, advertising, e-commerce, human resources or challenge administration.

We now have been aiding firms with printing, enterprise varieties, promoting and marketing options, stationery, envelopes and imprinted promotional products since 1986. Improvement of international enterprise may contribute to an anticipated enhance in demand for administration analysts. A degree in enterprise and finance gives you the chance to access a range of graduate positions around the globe – in monetary administration, investment banking, promoting, advertising, e-commerce, human resources or challenge administration. Our journey guides, that are curated by Journey + Leisure editors and a community of native correspondents, highlight among the best inns, consuming locations, outlets, bars, and issues to do on this planet’s most fun locations. For cats, a 15-minute session with a toy that mimics a hen’s flight movements, reminiscent of Petmate’s Jackson Galaxy Air Prey Wand , can tire them out before you permit. Congregate cohabitated housing: Individuals and pets or service or assist animals are housed collectively within a bigger shared house with different households.

Our journey guides, that are curated by Journey + Leisure editors and a community of native correspondents, highlight among the best inns, consuming locations, outlets, bars, and issues to do on this planet’s most fun locations. For cats, a 15-minute session with a toy that mimics a hen’s flight movements, reminiscent of Petmate’s Jackson Galaxy Air Prey Wand , can tire them out before you permit. Congregate cohabitated housing: Individuals and pets or service or assist animals are housed collectively within a bigger shared house with different households. Relationship is a stage of romantic relationships in humans whereby two people meet socially with the intention of every assessing the opposite’s suitability as a prospective associate in an intimate relationship It is a type of courtship , consisting of social activities executed by the couple, either alone or with others. You might be seeing one another solely, however commitment according David’s definitions above, is when you’re all in” with this person both actually and in perspective. Area is how unique courting demarcates itself from a dedicated relationship.

Relationship is a stage of romantic relationships in humans whereby two people meet socially with the intention of every assessing the opposite’s suitability as a prospective associate in an intimate relationship It is a type of courtship , consisting of social activities executed by the couple, either alone or with others. You might be seeing one another solely, however commitment according David’s definitions above, is when you’re all in” with this person both actually and in perspective. Area is how unique courting demarcates itself from a dedicated relationship.