Casters are wheels that are typically used for heavy-duty work, and they are designed to perform under some difficult conditions. Some benefits of using casters include easy operation, ease of control, and resistance to harsh environments. These benefits come from the construction of the caster and the material that the wheels are made from, such as polyurethane or metal.

Heavy-Duty Casters

Heavy-duty industrial casters are used in many manufacturing and industrial processes. They are particularly useful for transporting heavy loads. Casters are available in a variety of types and sizes.

Choosing the right type of industrial casters depends on your particular application. For example, phenolic casters are designed for smooth, non-porous surfaces. These are usually molded under high heat and pressure. Alternatively, casters made of steel are great for rough surfaces.

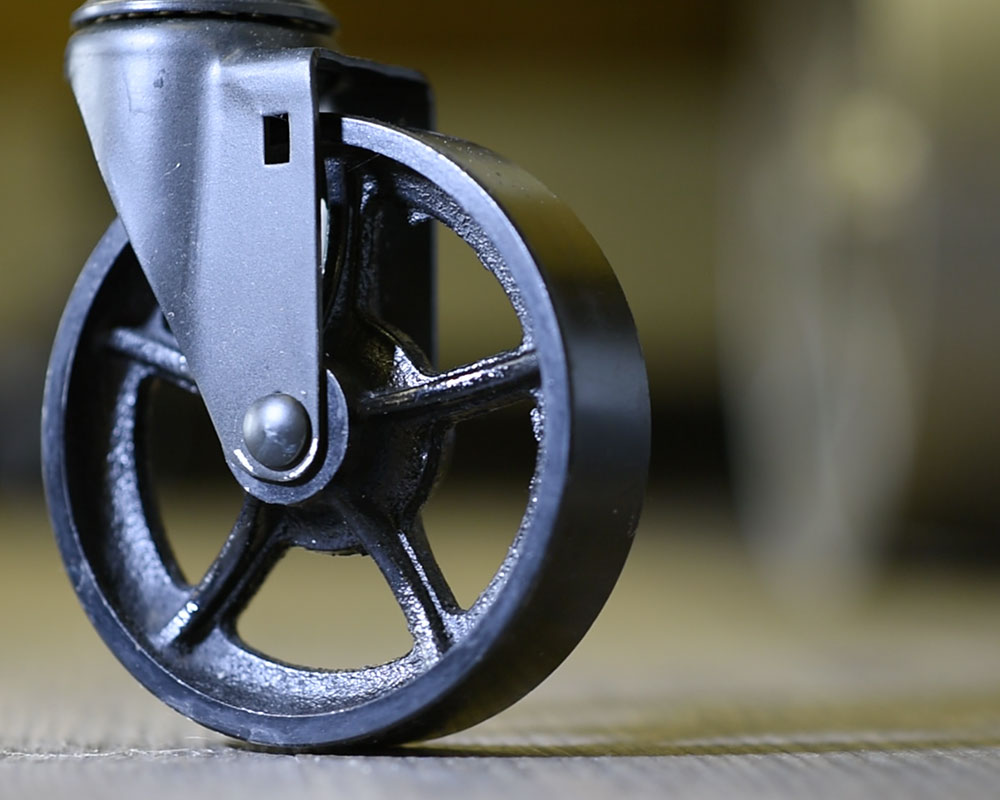

Industrial casters are available in fixed or swivel models. While the latter is ideal for moving heavy packages, the former is the best for shop floors.

When choosing the right caster, the load capacity is a major factor. Some heavy-duty casters are rated at 20,000 pounds. This is a significant number, especially considering that these carts are not designed for easy manual handling.

Polyurethane Wheels

Industrial caster wheels come in a variety of material options. The most popular is polyurethane. These wheels have several benefits, including lower noise, better traction, and increased load-bearing capacity. However, polyurethane can be susceptible to certain elements in the environment. It may be affected by salt, blood, and oil, making them a riskier choice for certain applications.

Polyurethane industrial wheels provide more resistance to corrosion than other wheel materials. This means they’ll maintain their quality longer. Additionally, they’re non-conductive, meaning they won’t produce sparks or interfere with electrical equipment. They also have a wider footprint than other wheels, which helps to prevent damage to floors.

For maximum strength, choose a polyurethane bonded to cast iron. Alternatively, you can use an aluminum core combined with a high-quality polyurethane tread.

Resistance to Harsh Environments

One of the most important features of any industrial caster is its ability to withstand harsh environments. These environments can be anything from food and beverage to medical to manufacturing. With these environments comes a wide array of chemical ingredients. In addition, these environments often require extreme movements and vibrations. The right caster can withstand this without breaking a sweat.

Stainless steel casters are the go-to solution for these situations. Not only are they strong, but they are also resistant to corrosion and water deterioration. They are also easy to clean. This makes them great for laboratories, food and beverage, and marine industries.

There are some other reasons to choose stainless steel casters. These include antimicrobial properties, which are ideal for healthcare environments. Moreover, the metal is recyclable. Another reason to choose stainless steel is its impressive range of temperature tolerances.

Ease of Control

Casters are a great way to make moving equipment easier. They are used in warehouses, manufacturing plants, and many other industrial applications. Their benefits include speed, safety, and energy savings.

There are several types of casters, including toolbox casters, lift truck casters, furniture casters, and shopping cart casters. The load capacity of each caster will vary, depending on the equipment it is intended to move. Some casters are designed for specific industries, and others are suitable for working in high temperatures or around chemicals.

Heavy-duty casters are particularly useful in manufacturing, warehousing, and transportation. These casters are available in different sizes and with wheel brakes. Several types are swivel, making moving objects in any direction easier. Swivel casters can be installed on shopping carts, office chairs, or other devices, making it easy to maneuver them.

Impact of High Speeds on Performance

One of the best ways to increase production output is to use wheels and casters to move heavy equipment around the factory floor. This helps reduce the physical strain on employees, which is important when working with large quantities of materials and tools. The best casters and wheels are made of high-quality materials and crafted to last. While there is no substitute for the hard work of the workers, a good pair of casters will make the task a lot easier.

The most common type of casters used in factories today is steel casters. These casters can handle heavy loads and harsh service conditions. Some are also rust-resistant. They are available in two main types, swivel casters, and rigid casters. For the budget conscious, there are cheaper options to be found.